Nickel

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| General properties | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Name, symbol | nickel, Ni | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Pronunciation |

/ˈnɪkəl/ NIK-əl | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Appearance | lustrous, metallic, and silver with a gold tinge | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Nickel in the periodic table | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Atomic number (Z) | 28 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Group, block | group 10, d-block | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Period | period 4 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Element category | transition metal | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Standard atomic weight (±) (Ar) | 58.6934(4)[1] | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Electron configuration |

[Ar] 3d8 4s2 or [Ar] 3d9 4s1 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

per shell | 2, 8, 16, 2 or 2, 8, 17, 1 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Physical properties | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Phase | solid | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Melting point | 1728 K (1455 °C, 2651 °F) | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Boiling point | 3003 K (2730 °C, 4946 °F) | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Density near r.t. | 8.908 g/cm3 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| when liquid, at m.p. | 7.81 g/cm3 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Heat of fusion | 17.48 kJ/mol | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Heat of vaporization | 379 kJ/mol | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Molar heat capacity | 26.07 J/(mol·K) | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Atomic properties | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Oxidation states | 4,[2] 3, 2, 1,[3] −1, −2 (a mildly basic oxide) | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Electronegativity | Pauling scale: 1.91 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Ionization energies |

1st: 737.1 kJ/mol 2nd: 1753.0 kJ/mol 3rd: 3395 kJ/mol (more) | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Atomic radius | empirical: 124 pm | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Covalent radius | 124±4 pm | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Van der Waals radius | 163 pm | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Miscellanea | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

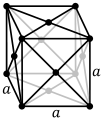

| Crystal structure |

face-centered cubic (fcc)  | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Speed of sound thin rod | 4900 m/s (at r.t.) | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Thermal expansion | 13.4 µm/(m·K) (at 25 °C) | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Thermal conductivity | 90.9 W/(m·K) | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Electrical resistivity | 69.3 nΩ·m (at 20 °C) | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Magnetic ordering | ferromagnetic | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Young's modulus | 200 GPa | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Shear modulus | 76 GPa | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Bulk modulus | 180 GPa | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Poisson ratio | 0.31 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Mohs hardness | 4.0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Vickers hardness | 638 MPa | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Brinell hardness | 667–1600 MPa | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| CAS Number | 7440-02-0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| History | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Discovery and first isolation | Axel Fredrik Cronstedt (1751) | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Most stable isotopes of nickel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

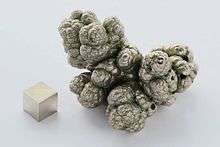

Nickel is a chemical element with symbol Ni and atomic number 28. It is a silvery-white lustrous metal with a slight golden tinge. Nickel belongs to the transition metals and is hard and ductile. Pure nickel, powdered to maximize the reactive surface area, shows a significant chemical activity, but larger pieces are slow to react with air under standard conditions because an oxide layer forms on the surface and prevents further corrosion (passivation). Even so, pure native nickel is found in Earth's crust only in tiny amounts, usually in ultramafic rocks,[4][5] and in the interiors of larger nickel–iron meteorites that were not exposed to oxygen when outside Earth's atmosphere.

Meteoric nickel is found in combination with iron, a reflection of the origin of those elements as major end products of supernova nucleosynthesis. An iron–nickel mixture is thought to compose Earth's inner core.[6]

Use of nickel (as a natural meteoric nickel–iron alloy) has been traced as far back as 3500 BCE. Nickel was first isolated and classified as a chemical element in 1751 by Axel Fredrik Cronstedt, who initially mistook the ore for a copper mineral. The element's name comes from a mischievous sprite of German miner mythology, Nickel (similar to Old Nick), that personified the fact that copper-nickel ores resisted refinement into copper. An economically important source of nickel is the iron ore limonite, which often contains 1–2% nickel. Nickel's other important ore minerals include garnierite, and pentlandite. Major production sites include the Sudbury region in Canada (which is thought to be of meteoric origin), New Caledonia in the Pacific, and Norilsk in Russia.

Nickel oxidizes slowly at room temperature and is considered corrosion-resistant. Historically, it has been used for plating iron and brass, coating chemistry equipment, and manufacturing certain alloys that retain a high silvery polish, such as German silver. About 6% of world nickel production is still used for corrosion-resistant pure-nickel plating. Nickel-plated objects sometimes provoke nickel allergy. Nickel has been widely used in coins, though its rising price has led to some replacement with cheaper metals in recent years.

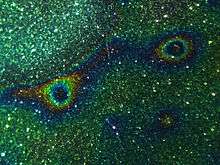

Nickel is one of four elements (iron, cobalt, nickel, and gadolinium)[7] that are ferromagnetic around room temperature. Alnico permanent magnets based partly on nickel are of intermediate strength between iron-based permanent magnets and rare-earth magnets. The metal is valuable in modern times chiefly in alloys; about 60% of world production is used in nickel-steels (particularly stainless steel). Other common alloys and some new superalloys comprise most of the remainder of world nickel use, with chemical uses for nickel compounds consuming less than 3% of production.[8] As a compound, nickel has a number of niche chemical manufacturing uses, such as a catalyst for hydrogenation. Nickel is an essential nutrient for some microorganisms and plants that have enzymes with nickel as an active site.

Properties

Atomic and physical properties

Nickel is a silvery-white metal with a slight golden tinge that takes a high polish. It is one of only four elements that are magnetic at or near room temperature, the others being iron, cobalt and gadolinium. Its Curie temperature is 355 °C (671 °F), meaning that bulk nickel is non-magnetic above this temperature.[10] The unit cell of nickel is a face-centered cube with the lattice parameter of 0.352 nm, giving an atomic radius of 0.124 nm. This crystal structure is stable to pressures of at least 70 GPa. Nickel belongs to the transition metals and is hard and ductile.

Electron configuration dispute

The nickel atom has two electron configurations, [Ar] 3d8 4s2 and [Ar] 3d9 4s1, which are very close in energy – the symbol [Ar] refers to the argon-like core structure. There is some disagreement on which configuration has the lowest energy.[11] Chemistry textbooks quote the electron configuration of nickel as [Ar] 4s2 3d8,[12] which can also be written [Ar] 3d8 4s2.[13] This configuration agrees with the Madelung energy ordering rule, which predicts that 4s is filled before 3d. It is supported by the experimental fact that the lowest energy state of the nickel atom is a 3d8 4s2 energy level, specifically the 3d8(3F) 4s2 3F, J = 4 level.[14]

However, each of these two configurations gives rise to several energy levels,[14] and the two sets of energy levels overlap. The average energy of states with configuration [Ar] 3d9 4s1 is actually lower than the average energy of states with configuration [Ar] 3d8 4s2. For this reason, the research literature on atomic calculations quotes the ground state configuration of nickel as [Ar] 3d9 4s1.[11]

Isotopes

The isotopes of nickel range in atomic weight from 48 u (48

Ni) to 78 u (78

Ni).

Naturally occurring nickel is composed of five stable isotopes; 58

Ni, 60

Ni, 61

Ni, 62

Ni and 64

Ni, with 58

Ni being the most abundant (68.077% natural abundance). Isotopes heavier than 62

Ni cannot be formed by nuclear fusion without losing energy.

Nickel-62 has the highest nuclear binding energy of any nuclide, at 8.7946 MeV/nucleon.[15] Its binding energy is greater than both 56

Fe, often incorrectly cited as the most tightly-bound nuclide, and it is also more tightly bound than 58

Fe.[16]

Stable isotope nickel-60 is the daughter product of the extinct radionuclide 60

Fe, which decays with a half-life of 2.6 million years. Because 60

Fe has such a long half-life, its persistence in materials in the solar system may generate observable variations in the isotopic composition of 60

Ni. Therefore, the abundance of 60

Ni present in extraterrestrial material may provide insight into the origin of the solar system and its early history.

Some 18 nickel radioisotopes have been characterised, the most stable being 59

Ni with a half-life of 76,000 years, 63

Ni with 100.1 years, and 56

Ni with 6.077 days. All of the remaining radioactive isotopes have half-lives that are less than 60 hours and the majority of these have half-lives that are less than 30 seconds. This element also has one meta state.[17]

Radioactive nickel-56 is produced by the silicon burning process and later set free in large quantities during type Ia supernovae. The shape of the light curve of these supernovae at intermediate to late-times corresponds to the decay via electron capture of nickel-56 to cobalt-56 and ultimately to iron-56.[18] Nickel-59 is a long-lived cosmogenic radionuclide with a half-life of 76,000 years. 59

Ni has found many applications in isotope geology. 59

Ni has been used to date the terrestrial age of meteorites and to determine abundances of extraterrestrial dust in ice and sediment. Nickel-78's half-life was recently measured at 110 milliseconds, and is believed an important isotope in supernova nucleosynthesis of elements heavier than iron.[19] The nuclide 48Ni, discovered in 1999, is the most proton-rich heavy element isotope known. With 28 protons and 20 neutrons 48Ni is "double magic" (like 208Pb) and therefore unusually stable.[17][20]

Occurrence

On Earth, nickel occurs most often in combination with sulfur and iron in pentlandite, with sulfur in millerite, with arsenic in the mineral nickeline, and with arsenic and sulfur in nickel galena.[21] Nickel is commonly found in iron meteorites as the alloys kamacite and taenite.

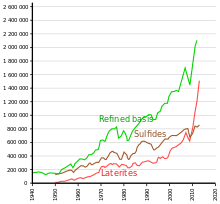

The bulk of the nickel is mined from two types of ore deposits. The first is laterite, where the principal ore minerals are nickeliferous limonite: (Fe, Ni)O(OH) and garnierite (a hydrous nickel silicate): (Ni, Mg)

3Si

2O

5(OH)

4. The second is magmatic sulfide deposits, where the principal ore mineral is pentlandite: (Ni, Fe)

9S

8.

Australia and New Caledonia have the biggest estimate reserves (45% all together).[22]

Identified land-based resources throughout the world averaging 1% nickel or greater comprise at least 130 million tons of nickel (about the double of known reserves). About 60% is in laterites and 40% in sulfide deposits.[22]

On geophysical evidence, most of the nickel on Earth is believed to be in the Earth's outer and inner cores. Kamacite and taenite are naturally occurring alloys of iron and nickel. For kamacite, the alloy is usually in the proportion of 90:10 to 95:5, although impurities (such as cobalt or carbon) may be present, while for taenite the nickel content is between 20% and 65%. Kamacite and taenite are also found in nickel iron meteorites.[23]

Compounds

The most common oxidation state of nickel is +2, but compounds of Ni0, Ni+, and Ni3+ are well known, and the exotic oxidation states Ni2−, Ni1−, and Ni4+ have been produced and studied.[24]

Nickel(0)

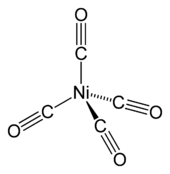

Nickel tetracarbonyl (Ni(CO)

4), discovered by Ludwig Mond,[25] is a volatile, highly toxic liquid at room temperature. On heating, the complex decomposes back to nickel and carbon monoxide:

- Ni(CO)

4 ⇌ Ni + 4 CO

This behavior is exploited in the Mond process for purifying nickel, as described above. The related nickel(0) complex bis(cyclooctadiene)nickel(0) is a useful catalyst in organonickel because the cod ligands are easily displaced.

Nickel(I)

Nickel(I) complexes are uncommon, but one example is the tetrahedral complex NiBr(PPh3)3. Many nickel(I) complexes feature Ni-Ni bonding, such as the dark red diamagnetic K

4[Ni

2(CN)

6] prepared by reduction of K

2[Ni

2(CN)

6] with sodium amalgam. This compound is oxidised in water, liberating H

2.[26]

It is thought that the nickel(I) oxidation state is important to nickel-containing enzymes, such as [NiFe]-hydrogenase, which catalyzes the reversible reduction of protons to H

2.[27]

_ion.png)

2(CN)

6]4−

ion[26]

Nickel(II)

_complexes_in_aqueous_solution.jpg)

3)

6]2+

, [Ni(C2H4(NH2)2)]2+, [NiCl

4]2−

, [Ni(H

2O)

6]2+

-sulfate-hexahydrate-sample.jpg)

Nickel(II) forms compounds with all common anions, including sulfide, sulfate, carbonate, hydroxide, carboxylates, and halides. Nickel(II) sulfate is produced in large quantities by dissolving nickel metal or oxides in sulfuric acid, forming both a hexa- and heptahydrates[28] useful for electroplating nickel. Common salts of nickel, such as the chloride, nitrate, and sulfate, dissolve in water to give green solutions of the metal aquo complex [Ni(H

2O)

6]2+

.

The four halides form nickel compounds, which are solids with molecules that feature octahedral Ni centres. Nickel(II) chloride is most common, and its behavior is illustrative of the other halides. Nickel(II) chloride is produced by dissolving nickel or its oxide in hydrochloric acid. It is usually encountered as the green hexahydrate, the formula of which is usually written NiCl2•6H2O. When dissolved in water, this salt forms the metal aquo complex [Ni(H

2O)

6]2+

. Dehydration of NiCl2•6H2O gives the yellow anhydrous NiCl

2.

Some tetracoordinate nickel(II) complexes, e.g. bis(triphenylphosphine)nickel chloride, exist both in tetrahedral and square planar geometries. The tetrahedral complexes are paramagnetic, whereas the square planar complexes are diamagnetic. In having properties of magnetic equilibrium and formation of octahedral complexes, they contrast with the divalent complexes of the heavier group 10 metals, palladium(II) and platinum(II), which form only square-planar geometry.[24]

Nickelocene is known; it has an electron count of 20, making it relatively unstable.

Nickel(III) and (IV)

Numerous Ni(III) compounds are known, with the first such examples being Nickel(III) trihalophosphines (NiIII(PPh3)X3).[29] Further, Ni(III) forms simple salts with fluoride[30] or oxide ions. Ni(III) can be stabilized by σ-donor ligands such as thiols and phosphines.[26]

Ni(IV) is present in the mixed oxide BaNiO

3, while Ni(III) is present in nickel(III) oxide, which is used as the cathode in many rechargeable batteries, including nickel-cadmium, nickel-iron, nickel hydrogen, and nickel-metal hydride, and used by certain manufacturers in Li-ion batteries.[31] Ni(IV) remains a rare oxidation state of nickel and very few compounds are known to date.[32][33][34][35]

History

Because the ores of nickel are easily mistaken for ores of silver, understanding of this metal and its use dates to relatively recent times. However, the unintentional use of nickel is ancient, and can be traced back as far as 3500 BCE. Bronzes from what is now Syria have been found to contain as much as 2% nickel.[36] Some ancient Chinese manuscripts suggest that "white copper" (cupronickel, known as baitong) was used there between 1700 and 1400 BCE. This Paktong white copper was exported to Britain as early as the 17th century, but the nickel content of this alloy was not discovered until 1822.[37]

In medieval Germany, a red mineral was found in the Erzgebirge (Ore Mountains) that resembled copper ore. However, when miners were unable to extract any copper from it, they blamed a mischievous sprite of German mythology, Nickel (similar to Old Nick), for besetting the copper. They called this ore Kupfernickel from the German Kupfer for copper.[38][39][40][41] This ore is now known to be nickeline (aka niccolite), a nickel arsenide. In 1751, Baron Axel Fredrik Cronstedt tried to extract copper from kupfernickel at a cobalt mine in the Swedish village of Los, and instead produced a white metal that he named after the spirit that had given its name to the mineral, nickel.[42] In modern German, Kupfernickel or Kupfer-Nickel designates the alloy cupronickel.

Originally, the only source for nickel was the rare Kupfernickel. Beginning in 1824, nickel was obtained as a byproduct of cobalt blue production. The first large-scale smelting of nickel began in Norway in 1848 from nickel-rich pyrrhotite. The introduction of nickel in steel production in 1889 increased the demand for nickel, and the nickel deposits of New Caledonia, discovered in 1865, provided most of the world's supply between 1875 and 1915. The discovery of the large deposits in the Sudbury Basin, Canada in 1883, in Norilsk-Talnakh, Russia in 1920, and in the Merensky Reef, South Africa in 1924, made large-scale production of nickel possible.[37]

Nickel has been a component of coins since the mid-19th century. Birmingham forged nickel coins in about 1833 for trading in Malaya.[43] In the United States, the term "nickel" or "nick" originally applied to the copper-nickel Flying Eagle cent, which replaced copper with 12% nickel 1857–58, then the Indian Head cent of the same alloy from 1859–1864. Still later, in 1865, the term designated the three-cent nickel, with nickel increased to 25%. In 1866, the five-cent shield nickel (25% nickel, 75% copper) appropriated the designation. Along with the alloy proportion, this term has been used to the present in the United States. Coins of nearly pure nickel were first used in 1881 in Switzerland, and 99.9% nickel five-cent coins were struck in Canada (the world's largest nickel producer at the time) during non-war years from 1922–1981; the metal content made these coins magnetic.[44] During the wartime period 1942–45, most or all nickel was removed from Canadian and U.S. coins to save it for strategic armor.[39][45] Canada used 99.9% nickel from 1968 in its higher-value coins until 2000. In the 21st century, the high price of nickel has led to some replacement of the metal in coins around the world. Coins still made with nickel alloys include one- and two-euro coins, 5¢, 10¢, 25¢ and 50¢ U.S. coins, and 20p, 50p, £1 and £2 UK coins. Nickel-alloy in 5p and 10p UK coins was replaced with nickel-plated steel began in 2012, causing allergy problems for some people and public controversy.[46]

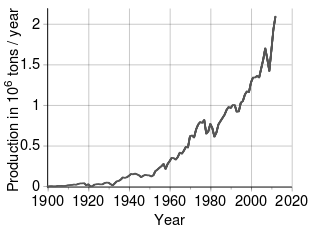

World production

The Philippines, Indonesia, Russia, Canada and Australia are the world's largest producers of nickel, as reported by the US Geological Survey.[22] The largest deposits of nickel in non-Russian Europe are located in Finland and Greece. Identified land-based resources averaging 1% nickel or greater contain at least 130 million tons of nickel. About 60% is in laterites and 40% is in sulfide deposits. In addition, extensive deep-sea resources of nickel are in manganese crusts and nodules covering large areas of the ocean floor, particularly in the Pacific Ocean.[48]

The one locality in the United States where nickel has been profitably mined is Riddle, Oregon, where several square miles of nickel-bearing garnierite surface deposits are located. The mine closed in 1987.[49][50] The Eagle mine project is a new nickel mine in Michigan's upper peninsula. Construction was completed in 2013, and operations began in the third quarter of 2014.[51] In the first full year of operation, Eagle Mine produced 18,000 tonnes.[51]

| Mine production and reserves[48] | 2012 (metric tons) | 2011 (metric tons) | Reserves (metric tons) |

|---|---|---|---|

| Australia | 230,000 | 215,000 | 20,000,000 |

| Botswana | 26,000 | 26,000 | 490,000 |

| Brazil | 140,000 | 209,000 | 7,500,000 |

| Canada | 220,000 | 220,000 | 3,300,000 |

| China | 91,000 | 89,800 | 3,000,000 |

| Colombia | 80,000 | 76,000 | 1,100,000 |

| Cuba | 72,000 | 71,000 | 5,500,000 |

| Dominican Republic | 24,000 | 21,700 | 970,000 |

| Indonesia | 320,000 | 290,000 | 3,900,000 |

| Madagascar | 22,000 | 5,900 | 1,600,000 |

| New Caledonia | 140,000 | 131,000 | 12,000,000 |

| Philippines | 330,000 | 270,000 | 1,100,000 |

| Russia | 270,000 | 267,000 | 6,100,000 |

| South Africa | 42,000 | 44,000 | 3,700,000 |

| Other countries | 120,000 | 103,000 | 4,600,000 |

| World total (metric tons, rounded) | 2,100,000 | 1,940,000 | 75,000,000 |

Extraction and purification

Nickel is obtained through extractive metallurgy: it is extracted from the ore by conventional roasting and reduction processes that yield a metal of greater than 75% purity. In many stainless steel applications, 75% pure nickel can be used without further purification, depending on the impurities.

Traditionally, most sulfide ores have been processed using pyrometallurgical techniques to produce a matte for further refining. Recent advances in hydrometallurgical techniques resulted in significantly purer metallic nickel product. Most sulfide deposits have traditionally been processed by concentration through a froth flotation process followed by pyrometallurgical extraction. In hydrometallurgical processes, nickel sulfide ores are concentrated with flotation (differential flotation if Ni/Fe ratio is too low) and then smelted. The nickel matte is further processed with the Sherritt-Gordon process. First, copper is removed by adding hydrogen sulfide, leaving a concentrate of cobalt and nickel. Then, solvent extraction is used to separate the cobalt and nickel, with the final nickel content greater than 99%.

Electrorefining

A second common refining process is leaching the metal matte into a nickel salt solution, followed by the electro-winning of the nickel from solution by plating it onto a cathode as electrolytic nickel.

Mond process

The purest metal is obtained from nickel oxide by the Mond process, which achieves a purity of greater than 99.99%.[52] The process was patented by Ludwig Mond and has been in industrial use since before the beginning of the 20th century. In this process, nickel is reacted with carbon monoxide in the presence of a sulfur catalyst at around 40–80 °C to form nickel carbonyl. Iron gives iron pentacarbonyl, too, but this reaction is slow. If necessary, the nickel may be separated by distillation. Dicobalt octacarbonyl is also formed in nickel distillation as a by-product, but it decomposes to tetracobalt dodecacarbonyl at the reaction temperature to give a non-volatile solid.[8]

Nickel is obtained from nickel carbonyl by one of two processes. It may be passed through a large chamber at high temperatures in which tens of thousands of nickel spheres, called pellets, are constantly stirred. The carbonyl decomposes and deposits pure nickel onto the nickel spheres. In the alternate process, nickel carbonyl is decomposed in a smaller chamber at 230 °C to create a fine nickel powder. The byproduct carbon monoxide is recirculated and reused. The highly pure nickel product is known as "carbonyl nickel".[53]

Metal value

The market price of nickel surged throughout 2006 and the early months of 2007; as of April 5, 2007, the metal was trading at US$52,300/tonne or $1.47/oz.[54] The price subsequently fell dramatically, and as of September 19, 2013, the metal was trading at $13,778/tonne, or $0.39/oz.[55][56]

The US nickel coin contains 0.04 ounces (1.1 g) of nickel, which at the April 2007 price was worth 6.5 cents, along with 3.75 grams of copper worth about 3 cents, with a total metal value of more than 9 cents. Since the face value of a nickel is 5 cents, this made it an attractive target for melting by people wanting to sell the metals at a profit. However, the United States Mint, in anticipation of this practice, implemented new interim rules on December 14, 2006, subject to public comment for 30 days, which criminalized the melting and export of cents and nickels.[57] Violators can be punished with a fine of up to $10,000 and/or imprisoned for a maximum of five years.

As of September 19, 2013, the melt value of a U.S. nickel (copper and nickel included) is $0.0450258, which is 90% of the face value.[58]

Applications

The global production of nickel is presently used as follows: 46% in nickel steel; 34% nonferrous alloys and superalloys; 14% electroplating, and 6% other uses.[22][59]

Nickel is used in many specific and recognizable industrial and consumer products, including stainless steel, alnico magnets, coinage, rechargeable batteries, electric guitar strings, microphone capsules, plating on plumbing fixtures,[60] and special alloys such as permalloy, elinvar, and invar. It is used for plating and as a green tint in glass. Nickel is preeminently an alloy metal, and its chief use is in nickel steels and nickel cast irons, in which it typically increases the tensile strength, toughness, and elastic limit. It is widely used in many other alloys, including nickel brasses and bronzes and alloys with copper, chromium, aluminium, lead, cobalt, silver, and gold (Inconel, Incoloy, Monel, Nimonic).[61]

Because it is resistant to corrosion, nickel was occasionally used as a substitute for decorative silver. Nickel was also occasionally used in some countries after 1859 as a cheap coinage metal (see above), but in the later years of the 20th century was replaced by cheaper stainless steel (i.e., iron) alloys, except in the United States and Canada.

Nickel is an excellent alloying agent for certain precious metals and is used in the fire assay as a collector of platinum group elements (PGE). As such, nickel is capable of fully collecting all 6 PGE elements from ores, and of partially collecting gold. High-throughput nickel mines may also engage in PGE recovery (primarily platinum and palladium); examples are Norilsk in Russia and the Sudbury Basin in Canada.

Nickel foam or nickel mesh is used in gas diffusion electrodes for alkaline fuel cells.[62][63]

Nickel and its alloys are frequently used as catalysts for hydrogenation reactions. Raney nickel, a finely divided nickel-aluminium alloy, is one common form, though related catalysts are also used, including Raney-type catalysts.

Nickel is a naturally magnetostrictive material, meaning that, in the presence of a magnetic field, the material undergoes a small change in length.[64][65] The magnetostriction of nickel is on the order of 50 ppm and is negative, indicating that it contracts.

Nickel is used as a binder in the cemented tungsten carbide or hardmetal industry and used in proportions of 6% to 12% by weight. Nickel makes the tungsten carbide magnetic and adds corrosion-resistance to the cemented parts, although the hardness is less than those with a cobalt binder.[66]

Biological role

Although not recognized until the 1970s, nickel is known to play an important role in the biology of some plants, eubacteria, archaebacteria, and fungi.[67][68] Nickel enzymes such as urease are considered virulence factors in some organisms.[69][70]

Urease catalyzes the hydrolysis of urea to form ammonia and carbamate.[68][67] The [NiFe]-hydrogenases can catalyze the oxidation of H

2 to form protons and electrons, and can also catalyze the reverse reaction, the reduction of protons to form hydrogen gas.[68][67] A nickel-tetrapyrrole coenzyme, cofactor F430, is present in methyl coenzyme M reductase, which can catalyze the formation of methane, or the reverse reaction, in methanogenic archaea.[71] One of the carbon monoxide dehydrogenase enzymes consists of an Fe-Ni-S cluster.[72] Other nickel-bearing enzymes include a rare bacterial class of superoxide dismutase[73] and glyoxalase I enzymes in bacteria and several parasitic eukaryotic trypanosomal parasites[74] (in higher organisms, including yeast and mammals, this enzyme contains divalent Zn2+).[75][76][77][78][79]

Nickel is implicated in the catalytic formation of the hard calcium carbonate plates of the spiny tests on larval sea urchins.[80]

Nickel can affect human health through infections by nickel-dependent bacteria.[81] Nickel released from Siberian Traps volcanic eruptions (site of the modern city of Norilsk) is suspected of assisting the growth of Methanosarcina, a genus of euryarchaeote archaea that produced methane during the biggest extinction event on record.[82]

Toxicity

The major source of nickel exposure is oral consumption. Nickel is found naturally in both food and water, and may be increased by human pollution. For example, nickel-plated faucets may contaminate water and soil; mining and smelting may dump nickel into waste-water; nickel–steel alloy cookware and nickel-pigmented dishes may release nickel into food. The atmosphere may be polluted by nickel metal refining and fossil fuel combustion. Humans may absorb nickel directly from tobacco smoke and skin contact with jewelry, shampoos, detergents, and coins. A less-common form of chronic exposure is through hemodialysis as traces of nickel ions may be absorbed into the plasma from the chelating action of albumin.

The average daily exposure does not pose a threat to human health. Most of the nickel absorbed every day by humans is removed by the kidneys and passed out of the body through urine or is eliminated through the gastrointestinal tract without being absorbed. Nickel is not a cumulative poison, but larger doses or chronic exposure may be toxic, even carcinogenic, and constitute an occupational hazard.[83]

In the US, the minimal risk level of nickel and its compounds is set to 0.2 µg/m3 for inhalation during 15–364 days.[84] Nickel sulfide fume and dust are believed carcinogenic, and various other nickel compounds may be as well.[85][86][87] Nickel carbonyl [Ni(CO)

4] is an extremely toxic gas. The toxicity of metal carbonyls is a function of both the toxicity of the metal and the off-gassing of carbon monoxide from the carbonyl functional groups; nickel carbonyl is also explosive in air.[88][89]

People can be exposed to nickel in the workplace by inhalation, ingestion, and contact with skin or eye. The Occupational Safety and Health Administration (OSHA) has set the legal limit (permissible exposure limit) for the workplace at 1 mg/m3 per 8-hour workday, excluding nickel carbonyl. The National Institute for Occupational Safety and Health (NIOSH) specifies the recommended exposure limit (REL) of 0.015 mg/m3 per 8-hour workday. At 10 mg/m3, nickel is immediately dangerous to life and health.[90]

In the US, the Tolerable Upper Limit of dietary nickel is 1000 µg/day,[91] while estimated average ingestion is 69–162 µg/day.[92] Large amounts of nickel (and chromium) – comparable to the estimated average ingestion above – leach into food cooked in stainless steel. For example, the amount of nickel leached after 10 cooking cycles into one serving of tomato sauce averages 88 µg.[93][94]

Sensitized individuals may show a skin contact allergy to nickel known as a contact dermatitis. Highly sensitized individuals may also react to foods with high nickel content.[95] Sensitivity to nickel may also be present in patients with pompholyx. Nickel is the top confirmed contact allergen worldwide, partly due to its use in jewelry for pierced ears.[96] Nickel allergies affecting pierced ears are often marked by itchy, red skin. Many earrings are now made without nickel or low-release nickel[97] to address this problem. The amount allowed in products that contact human skin is now regulated by the European Union. In 2002, researchers found that the nickel released by 1 and 2 Euro coins was far in excess of those standards. This is believed to be the result of a galvanic reaction.[98] Nickel was voted Allergen of the Year in 2008 by the American Contact Dermatitis Society.[99] In August 2015, the American Academy of Dermatology adopted a position statement on the safety of nickel: "Estimates suggest that contact dermatitis, which includes nickel sensitization, accounts for approximately $1.918 billion and affects nearly 72.29 million people."[95]

Reports show that both the nickel-induced activation of hypoxia-inducible factor (HIF-1) and the up-regulation of hypoxia-inducible genes are caused by depletion of intracellular ascorbate. The addition of ascorbate to the culture medium increased the intracellular ascorbate level and reversed both the metal-induced stabilization of HIF-1- and HIF-1α-dependent gene expression.[100][101]

See also

- Category:Nickel alloys

- Nickel aluminide

References

- ↑ Standard Atomic Weights 2013. Commission on Isotopic Abundances and Atomic Weights

- ↑ Carnes, Matthew; Buccella, Daniela; Chen, Judy Y.-C.; Ramirez, Arthur P.; Turro, Nicholas J.; Nuckolls, Colin; Steigerwald, Michael (2009). "A Stable Tetraalkyl Complex of Nickel(IV)". Angewandte Chemie International Edition. 48 (2): 3384. doi:10.1002/anie.200804435.

- ↑ Pfirrmann, Stefan; Limberg, Christian; Herwig, Christian; Stößer, Reinhard; Ziemer, Burkhard (2009). "A Dinuclear Nickel(I) Dinitrogen Complex and its Reduction in Single-Electron Steps". Angewandte Chemie International Edition. 48 (18): 3357. doi:10.1002/anie.200805862.

- ↑ "Nickel – Handbook of Mineralogy" (PDF). Handbookofmineralogy.org. Retrieved 2016-03-02.

- ↑ "Nickel: Nickel mineral information and data". Mindat.org. Retrieved 2016-03-02.

- ↑ Stixrude, Lars; Waserman, Evgeny; Cohen, Ronald (November 1997). "Composition and temperature of Earth's inner core". Journal of Geophysical Research. American Geophysical Union. 102 (B11): 24729–24740. Bibcode:1997JGR...10224729S. doi:10.1029/97JB02125.

- ↑ Coey, J.M.D.; Skumryev, V.; Gallagher, K. (1999). "Rare-earth metals: Is gadolinium really ferromagnetic?". Nature. 401 (6748): 35–36. doi:10.1038/43363. ISSN 0028-0836.

- 1 2 Derek G. E. Kerfoot (2005), "Nickel", Ullmann's Encyclopedia of Industrial Chemistry, Weinheim: Wiley-VCH, doi:10.1002/14356007.a17_157

- ↑ Shiozawa, Hidetsugu; Briones-Leon, Antonio; Domanov, Oleg; Zechner, Georg; et al. (2015). "Nickel clusters embedded in carbon nanotubes as high performance magnets". Scientific Reports. 5: 15033. doi:10.1038/srep15033. PMC 4602218

. PMID 26459370.

. PMID 26459370. - ↑ Kittel, Charles (1996). Introduction to Solid State Physics. Wiley. p. 449. ISBN 0-471-14286-7.

- 1 2 Scerri, Eric R. (2007). The periodic table: its story and its significance. Oxford University Press. pp. 239–240. ISBN 0-19-530573-6.

- ↑ Miessler, G.L. and Tarr, D.A. (1999) Inorganic Chemistry 2nd ed., Prentice–Hall. p. 38. ISBN 0138418918.

- ↑ Petrucci, R.H. et al. (2002) General Chemistry 8th ed., Prentice–Hall. p. 950. ISBN 0130143294.

- 1 2 NIST Atomic Spectrum Database To read the nickel atom levels, type "Ni I" in the Spectrum box and click on Retrieve data.

- ↑ "The Most Tightly Bound Nuclei". Retrieved November 19, 2008.

- ↑ Fewell, M. P. (1995). "The atomic nuclide with the highest mean binding energy". American Journal of Physics. 63 (7): 653. doi:10.1119/1.17828.

- 1 2 Audi, Georges; Bersillon, O.; Blachot, J.; Wapstra, A.H. (2003). "The NUBASE Evaluation of Nuclear and Decay Properties". Nuclear Physics A. Atomic Mass Data Center. 729: 3–128. Bibcode:2003NuPhA.729....3A. doi:10.1016/j.nuclphysa.2003.11.001.

- ↑ Pagel, Bernard Ephraim Julius. "Further burning stages: evolution of massive stars". Nucleosynthesis and chemical evolution of galaxies. pp. 154–160. ISBN 978-0-521-55958-4.

- ↑ Castelvecchi, Davide (April 22, 2005). "Atom Smashers Shed Light on Supernovae, Big Bang". Retrieved November 19, 2008.

- ↑ W, P (October 23, 1999). "Twice-magic metal makes its debut – isotope of nickel". Science News. Retrieved September 29, 2006.

- ↑ National Pollutant Inventory – Nickel and compounds Fact Sheet. Npi.gov.au. Retrieved on January 9, 2012.

- 1 2 3 4 Kuck, Peter H. "Mineral Commodity Summaries 2012: Nickel" (PDF). United States Geological Survey. Retrieved November 19, 2008.

- ↑ Rasmussen, K. L.; Malvin, D. J.; Wasson, J. T. (1988). "Trace element partitioning between taenite and kamacite – Relationship to the cooling rates of iron meteorites". Meteoritics. 23 (2): a107–112. Bibcode:1988Metic..23..107R. doi:10.1111/j.1945-5100.1988.tb00905.x.

- 1 2 Greenwood, Norman N.; Earnshaw, Alan (1997). Chemistry of the Elements (2nd ed.). Butterworth-Heinemann. ISBN 0-08-037941-9.

- ↑ "The Extraction of Nickel from its Ores by the Mond Process". Nature. 59 (1516): 63–64. 1898. Bibcode:1898Natur..59...63.. doi:10.1038/059063a0.

- 1 2 3 Housecroft, C. E.; Sharpe, A. G. (2008). Inorganic Chemistry (3rd ed.). Prentice Hall. p. 729. ISBN 978-0131755536.

- ↑ Housecroft, C. E.; Sharpe, A. G. (2012). Inorganic Chemistry (4th ed.). Prentice Hall. p. 764. ISBN 978-0273742753.

- ↑ Keith Lascelles, Lindsay G. Morgan, David Nicholls, Detmar Beyersmann "Nickel Compounds" in Ullmann's Encyclopedia of Industrial Chemistry 2005, Wiley-VCH, Weinheim. doi:10.1002/14356007.a17_235.pub2

- ↑ Jensen, K. A. (1936). "Zur Stereochemie des koordinativ vierwertigen Nickels". Zeitschrift für anorganische und allgemeine Chemie. 229 (3): 265–281. doi:10.1002/zaac.19362290304.

- ↑ Court, T. L.; Dove, M. F. A. (1973). "Fluorine compounds of nickel(III)". Journal of the Chemical Society, Dalton Transactions (19): 1995. doi:10.1039/DT9730001995.

- ↑ "Imara Corporation Launches; New Li-ion Battery Technology for High-Power Applications". Green Car Congress. December 18, 2008.

- ↑ Spokoyny, Alexander M.; Li, Tina C.; Farha, Omar K.; Machan, Charles M.; She, Chunxing; Stern, Charlotte L.; Marks, Tobin J.; Hupp, Joseph T.; Mirkin, Chad A. (28 June 2010). "Electronic Tuning of Nickel-Based Bis(dicarbollide) Redox Shuttles in Dye-Sensitized Solar Cells". Angew. Chem. Int. Ed.: 5339–5343. doi:10.1002/anie.201002181.

- ↑ Hawthorne, M. Frederick (1967). "(3)-1,2-Dicarbollyl Complexes of Nickel(III) and Nickel(IV)". Journal of the American Chemical Society. 89: 470–471. doi:10.1021/ja00978a065.

- ↑ Camasso, N. M.; Sanford, M. S. (2015). "Design, synthesis, and carbon-heteroatom coupling reactions of organometallic nickel(IV) complexes". Science. 347 (6227): 1218–20. doi:10.1126/science.aaa4526. PMID 25766226.

- ↑ Baucom, E. I.; Drago, R. S. (1971). "Nickel(II) and nickel(IV) complexes of 2,6-diacetylpyridine dioxime". Journal of the American Chemical Society. 93 (24): 6469–6475. doi:10.1021/ja00753a022.

- ↑ Rosenberg, Samuel J (1968). Nickel and Its Alloys. National Bureau of Standards.

- 1 2 McNeil, Ian (1990). "The Emergence of Nickel". An Encyclopaedia of the History of Technology. Taylor & Francis. pp. 96–100. ISBN 978-0-415-01306-2.

- ↑ Chambers Twentieth Century Dictionary, p888, W&R Chambers Ltd., 1977.

- 1 2 Baldwin, W. H. (1931). "The story of Nickel. I. How "Old Nick's" gnomes were outwitted". Journal of Chemical Education. 8 (9): 1749. Bibcode:1931JChEd...8.1749B. doi:10.1021/ed008p1749.

- ↑ Baldwin, W. H. (1931). "The story of Nickel. II. Nickel comes of age". Journal of Chemical Education. 8 (10): 1954. Bibcode:1931JChEd...8.1954B. doi:10.1021/ed008p1954.

- ↑ Baldwin, W. H. (1931). "The story of Nickel. III. Ore, matte, and metal". Journal of Chemical Education. 8 (12): 2325. Bibcode:1931JChEd...8.2325B. doi:10.1021/ed008p2325.

- ↑ Weeks, Mary Elvira (1932). "The discovery of the elements: III. Some eighteenth-century metals". Journal of Chemical Education. 9: 22. Bibcode:1932JChEd...9...22W. doi:10.1021/ed009p22.

- ↑ "nikkelen dubbele wapenstuiver Utrecht". nederlandsemunten.nl.

- ↑ "Industrious, enduring–the 5-cent coin". Royal Canadian Mint. 2008. Retrieved January 10, 2009.

- ↑ Molloy, Bill (November 8, 2001). "Trends of Nickel in Coins – Past, Present and Future". The Nickel Institute. Archived from the original on September 29, 2006. Retrieved November 19, 2008.

- ↑ Lacey, Anna (June 22, 2013). "A bad penny? New coins and nickel allergy". BBC Health Check. Retrieved July 25, 2013.

- ↑ Kelly, T. D.; Matos, G. R. "Nickel Statistics" (PDF). U.S. Geological Survey. Retrieved 2014-08-11.

- 1 2 "Nickel" (PDF). U.S. Geological Survey, Mineral Commodity Summaries. January 2013.

- ↑ "The Nickel Mountain Project" (PDF). Ore Bin. 15 (10): 59–66. 1953.

- ↑ "Environment Writer: Nickel". National Safety Council. 2006. Retrieved January 10, 2009.

- 1 2 "Operations & Development". Lundin Mining Corporation. Retrieved 2014-08-10.

- ↑ Mond, L.; Langer, K.; Quincke, F. (1890). "Action of carbon monoxide on nickel". Journal of the Chemical Society. 57: 749–753. doi:10.1039/CT8905700749.

- ↑ Neikov, Oleg D.; Naboychenko, Stanislav; Gopienko, Victor G & Frishberg, Irina V (January 15, 2009). Handbook of Non-Ferrous Metal Powders: Technologies and Applications. Elsevier. pp. 371–. ISBN 978-1-85617-422-0. Retrieved January 9, 2012.

- ↑ "LME nickel price graphs". London Metal Exchange. Retrieved June 6, 2009.

- ↑ "Nickel Prices and Nickel Price Charts". Infomine.com. 2013-07-10. Retrieved 2014-08-10.

- ↑ "Nickel Price". Investing.com.

- ↑ United States Mint Moves to Limit Exportation & Melting of Coins, The United States Mint, press release, December 14, 2006

- ↑ "United States Circulating Coinage Intrinsic Value Table". Coininflation.com. Retrieved September 13, 2013.

- ↑ Kuck, Peter H. "Mineral Yearbook 2006: Nickel" (PDF). United States Geological Survey. Retrieved November 19, 2008.

- ↑ Engineer, Engineering Record, Building Record, and Sanitary (1896-01-01). American Plumbing Practice: From the Engineering Record (Prior to 1887 the Sanitary Engineer.) A Selected Reprint of Articles Describing Notable Plumbing Installations in the United States, and Questions and Answers on Problems Arising in Plumbing and House Draining. With Five Hundred and Thirty-six Illustrations. Engineering record. p. 119.

- ↑ Davis, Joseph R (2000). "Uses of Nickel". ASM Specialty Handbook: Nickel, Cobalt, and Their Alloys. ASM International. pp. 7–13. ISBN 978-0-87170-685-0.

- ↑ Kharton, Vladislav V. (2011). Solid State Electrochemistry II: Electrodes, Interfaces and Ceramic Membranes. Wiley-VCH. pp. 166–. ISBN 978-3-527-32638-9.

- ↑ Bidault, F.; Brett, D. J. L.; Middleton, P. H.; Brandon, N. P. "A New Cathode Design for Alkaline Fuel Cells(AFCs)" (PDF). Imperial College London. Archived from the original (PDF) on 2011-07-20.

- ↑ UCLA – Magnetostrictive Materials Overview. Aml.seas.ucla.edu. Retrieved on January 9, 2012. Archived September 5, 2013, at the Wayback Machine.

- ↑ Angara, Raghavendra (2009). High Frequency High Amplitude Magnetic Field Driving System for Magnetostrictive Actuators. p. 5. ISBN 9781109187533.

- ↑ Cheburaeva, R. F.; Chaporova, I. N.; Krasina, T. I. (1992). "Structure and properties of tungsten carbide hard alloys with an alloyed nickel binder". Soviet Powder Metallurgy and Metal Ceramics. 31 (5): 423–425. doi:10.1007/BF00796252.

- 1 2 3 Astrid Sigel; Helmut Sigel; Roland K. O. Sigel, eds. (2008). Nickel and Its Surprising Impact in Nature. Metal Ions in Life Sciences. 2. Wiley. ISBN 978-0-470-01671-8.

- 1 2 3 Sydor, Andrew; Zamble, Deborah (2013). Banci, Lucia, ed. Nickel Metallomics: General Themes Guiding Nickel Homeostasis. Dordrecht: Springer. pp. 375–416. ISBN 978-94-007-5561-1.

- ↑ Covacci, Antonello; Telford, John L.; Giudice, Giuseppe Del; Parsonnet, Julie; Rappuoli, Rino (1999-05-21). "Helicobacter pylori Virulence and Genetic Geography". Science. 284 (5418): 1328–1333. doi:10.1126/science.284.5418.1328. ISSN 0036-8075. PMID 10334982.

- ↑ Cox, Gary M.; Mukherjee, Jean; Cole, Garry T.; Casadevall, Arturo; Perfect, John R. (2000-02-01). "Urease as a Virulence Factor in Experimental Cryptococcosis". Infection and Immunity. 68 (2): 443–448. doi:10.1128/IAI.68.2.443-448.2000. ISSN 0019-9567. PMID 10639402.

- ↑ Stephen W., Ragdale (2014). "Chapter 6. Biochemistry of Methyl-Coenzyme M Reductase: The Nickel Metalloenzyme that Catalyzes the Final Step in Synthesis and the First Step in Anaerobic Oxidation of the Greenhouse Gas Methane". In Peter M.H. Kroneck; Martha E. Sosa Torres. The Metal-Driven Biogeochemistry of Gaseous Compounds in the Environment. Metal Ions in Life Sciences. 14. Springer. pp. 125–145. doi:10.1007/978-94-017-9269-1_6.

- ↑ Wang, Vincent C.-C.; Ragsdale, Stephen W.; Armstrong, Fraser A. (2014). "Chapter 4. Investigations of the Efficient Electrocatalytic Interconversions of Carbon Dioxide and Carbon Monoxide by Nickel-Containing Carbon Monoxide Dehydrogenases". In Peter M.H. Kroneck; Martha E. Sosa Torres. The Metal-Driven Biogeochemistry of Gaseous Compounds in the Environment. Metal Ions in Life Sciences. 14. Springer. pp. 71–97. doi:10.1007/978-94-017-9269-1_4.

- ↑ Szilagyi, R. K.; Bryngelson, P. A.; Maroney, M. J.; Hedman, B.; et al. (2004). "S K-Edge X-ray Absorption Spectroscopic Investigation of the Ni-Containing Superoxide Dismutase Active Site: New Structural Insight into the Mechanism". Journal of the American Chemical Society. 126 (10): 3018–3019. doi:10.1021/ja039106v. PMID 15012109.

- ↑ Greig N; Wyllie S; Vickers TJ; Fairlamb AH (2006). "Trypanothione-dependent glyoxalase I in Trypanosoma cruzi". Biochemical Journal. 400 (2): 217–23. doi:10.1042/BJ20060882. PMC 1652828

. PMID 16958620.

. PMID 16958620. - ↑ Aronsson A-C; Marmstål E; Mannervik B (1978). "Glyoxalase I, a zinc metalloenzyme of mammals and yeast". Biochemical and Biophysical Research Communications. 81 (4): 1235–1240. doi:10.1016/0006-291X(78)91268-8. PMID 352355.

- ↑ Ridderström M; Mannervik B (1996). "Optimized heterologous expression of the human zinc enzyme glyoxalase I". Biochemical Journal. 314 (Pt 2): 463–467. PMC 1217073

. PMID 8670058.

. PMID 8670058. - ↑ Saint-Jean AP; Phillips KR; Creighton DJ; Stone MJ (1998). "Unknown title". Biochemistry. 37 (29): 10345–10353. doi:10.1021/bi980868q. PMID 9671502.

- ↑ Thornalley, P. J. (2003). "Glyoxalase I—structure, function and a critical role in the enzymatic defence against glycation". Biochemical Society Transactions. 31 (Pt 6): 1343–1348. doi:10.1042/BST0311343. PMID 14641060.

- ↑ Vander Jagt DL (1989). "Unknown chapter title". In D Dolphin; R Poulson; O Avramovic. Coenzymes and Cofactors VIII: Glutathione Part A. New York: John Wiley and Sons.

- ↑ "Sea urchins reveal promising carbon capture alternative". Gizmag. 4 February 2013. Retrieved 11 July 2016.

- ↑ Zambelli, Barbara; Ciurli, Stefano (2013). "Chapter 10. Nickel: and Human Health". In Astrid Sigel; Helmut Sigel; Roland K. O. Sigel. Interrelations between Essential Metal Ions and Human Diseases. Metal Ions in Life Sciences. 13. Springer. pp. 321–357. doi:10.1007/978-94-007-7500-8_10.

- ↑ Schirber, Michael (July 27, 2014). "Microbe's Innovation May Have Started Largest Extinction Event on Earth". Space.com. Astrobiology Magazine.

.... That spike in nickel allowed methanogens to take off.

- ↑ Butticè, Claudio (2015). "Nickel Compounds". In Colditz, Graham A. The SAGE Encyclopedia of Cancer and Society (Second ed.). Thousand Oaks: SAGE Publications, Inc. pp. 828–831. ISBN 9781483345734.

- ↑ ToxGuideTM for Nickel. U.S. Department of Health and Human Services. Agency for Toxic Substances and Disease Registry

- ↑ Kasprzak; Sunderman Jr., F. W.; Salnikow, K. (2003). "Nickel carcinogenesis". Mutation research. 533 (1–2): 67–97. doi:10.1016/j.mrfmmm.2003.08.021. PMID 14643413.

- ↑ Dunnick, JK; Elwell, M. R.; Radovsky, A. E.; Benson, J. M.; et al. (1995). "Comparative carcinogenic effects of nickel subsulfide, nickel oxide, or nickel sulfate hexahydrate chronic exposures in the lung". Cancer Research. 55 (22): 5251–6. PMID 7585584.

- ↑ Methods to Develop Inhalation Cancer Risk Estimates for Chromium and Nickel Compounds. Research Triangle Park, NC: U.S. Environmental Protection Agency, Office of Air Quality Planning and Standards, Health and Environmental Impacts Division. October 2011. Retrieved 19 March 2015.

- ↑ Stellman, Jeanne Mager (1998). Encyclopaedia of Occupational Health and Safety: Chemical, industries and occupations. International Labour Organization. pp. 133–. ISBN 978-92-2-109816-4. Retrieved January 9, 2012.

- ↑ Barceloux, Donald G.; Barceloux, Donald (1999). "Nickel". Clinical Toxicology. 37 (2): 239–258. doi:10.1081/CLT-100102423. PMID 10382559.

- ↑ "CDC – NIOSH Pocket Guide to Chemical Hazards – Nickel metal and other compounds (as Ni)". www.cdc.gov. Retrieved 2015-11-20.

- ↑ Trumbo P; Yates AA; Schlicker S; Poos M (March 2001). "Dietary reference intakes: vitamin A, vitamin K, arsenic, boron, chromium, copper, iodine, iron, manganese, molybdenum, nickel, silicon, vanadium, and zinc". Journal of the American Dietetic Association. 101 (3): 294–301. doi:10.1016/S0002-8223(01)00078-5. PMID 11269606.

- ↑ Agency for Toxic Substances; Disease Registry (August 2005). Toxicological Profile for Nickel. US Public Health Service.

- ↑ Kamerud KL; Hobbie KA; Anderson KA (August 28, 2013). "Stainless Steel Leaches Nickel and Chromium into Foods During Cooking". Journal of Agricultural and Food Chemistry. 61 (39): 9495–501. doi:10.1021/jf402400v. PMID 23984718.

- ↑ Flint GN; Packirisamy S (Feb–Mar 1997). "Purity of food cooked in stainless steel utensils". Food Additives & Contaminants. 14 (2): 115–26. doi:10.1080/02652039709374506. PMID 9102344.

- 1 2 Position Statement on Nickel Sensitivity. American Academy of Dermatology(August 22, 2015)

- ↑ Thyssen J. P.; Linneberg A.; Menné T.; Johansen J. D. (2007). "The epidemiology of contact allergy in the general population—prevalence and main findings". Contact Dermatitis. 57 (5): 287–99. doi:10.1111/j.1600-0536.2007.01220.x. PMID 17937743.

- ↑ Dermal Exposure: Nickel Alloys Nickel Producers Environmental Research Association (NiPERA), accessed 2016 Feb.11

- ↑ Nestle, O.; Speidel, H.; Speidel, M. O. (2002). "High nickel release from 1- and 2-euro coins". Nature. 419 (6903): 132. Bibcode:2002Natur.419..132N. doi:10.1038/419132a. PMID 12226655.

- ↑ Dow, Lea (June 3, 2008). "Nickel Named 2008 Contact Allergen of the Year". Nickel Allergy Information. Archived from the original on 2009-02-03.

- ↑ Salnikow, k.; Donald, S. P.; Bruick, R. K.; Zhitkovich, A.; et al. (September 2004). "Depletion of intracellular ascorbate by the carcinogenic metal nickel and cobalt results in the induction of hypoxic stress". Journal of Biological Chemistry. 279 (39): 40337–44. doi:10.1074/jbc.M403057200. PMID 15271983.

- ↑ Das, K. K.; Das, S. N.; Dhundasi, S. A. (2008). "Nickel, its adverse health effects and oxidative stress" (PDF). Indian Journal of Medical Research. 128 (4): 117–131. PMID 19106437. Retrieved August 22, 2011.

External links

| Wikimedia Commons has media related to Nickel. |

| Look up nickel in Wiktionary, the free dictionary. |

- Nickel at The Periodic Table of Videos (University of Nottingham)

- CDC – Nickel – NIOSH Workplace Safety and Health Topic

- An occupational hygiene assessment of dermal nickel exposures in primary production industries by GW Hughson. Institute of Occupational Medicine Research Report TM/04/05

- An occupational hygiene assessment of dermal nickel exposures in primary production and primary user industries. Phase 2 Report by GW Hughson. Institute of Occupational Medicine Research Report TM/05/06

- "The metal that brought you cheap flights", BBC

| Periodic table (Large cells) | |||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | ||||||||||||||||

| 1 | H | He | |||||||||||||||||||||||||||||||

| 2 | Li | Be | B | C | N | O | F | Ne | |||||||||||||||||||||||||

| 3 | Na | Mg | Al | Si | P | S | Cl | Ar | |||||||||||||||||||||||||

| 4 | K | Ca | Sc | Ti | V | Cr | Mn | Fe | Co | Ni | Cu | Zn | Ga | Ge | As | Se | Br | Kr | |||||||||||||||

| 5 | Rb | Sr | Y | Zr | Nb | Mo | Tc | Ru | Rh | Pd | Ag | Cd | In | Sn | Sb | Te | I | Xe | |||||||||||||||

| 6 | Cs | Ba | La | Ce | Pr | Nd | Pm | Sm | Eu | Gd | Tb | Dy | Ho | Er | Tm | Yb | Lu | Hf | Ta | W | Re | Os | Ir | Pt | Au | Hg | Tl | Pb | Bi | Po | At | Rn | |

| 7 | Fr | Ra | Ac | Th | Pa | U | Np | Pu | Am | Cm | Bk | Cf | Es | Fm | Md | No | Lr | Rf | Db | Sg | Bh | Hs | Mt | Ds | Rg | Cn | Nh | Fl | Mc | Lv | Ts | Og | |

|

| |||||||||||||||||||||||||||||||||